Understanding Industrial Air Quality Control with Baghouse Technology

Baghouse dust collectors are industrial air-pollution control devices that remove dust and particulate matter from manufacturing processes using bag- or cartridge-type filter media. They’re the most common and cost-effective solution for controlling airborne contaminants in facilities worldwide.

Quick Overview:

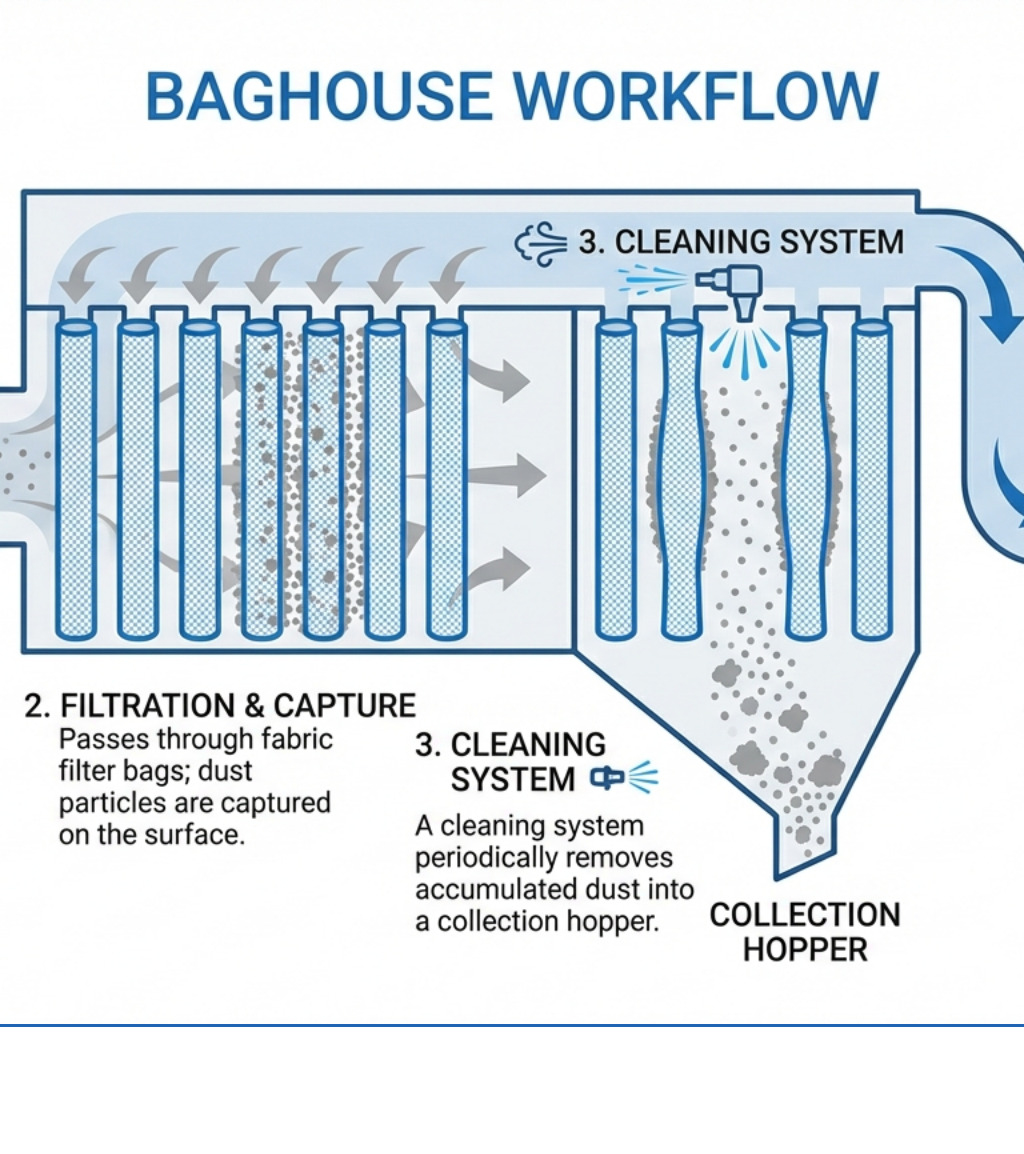

- What they are: Fabric filter systems capture dust by passing contaminated air passes through a baghouse, where particulate matter collects on the filter bags or cartridges

- How they work: A fan draws contaminated air into the housing, where dust collects on the filter surfaces, and clean air exits through the top.

- Collection efficiency: Typically, 99% or better, even for very small particles

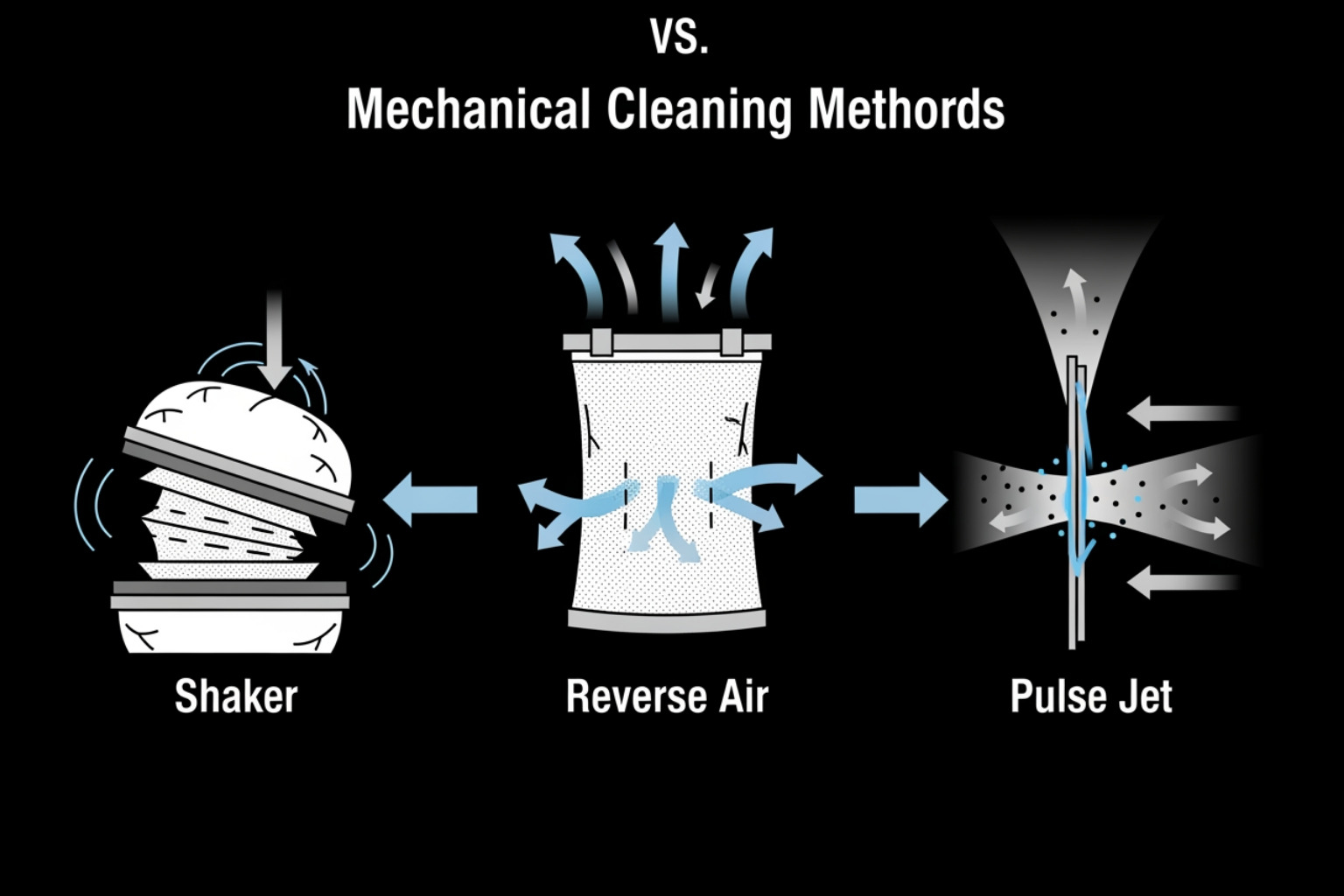

- Cleaning methods: Pulse-clean bag and cartridge filters use bursts of compressed air to dislodge collected dust. Reverse-air systems use low-pressure, high-volume air for cleaning, while shaker-style units rely on mechanical agitation to clean the filters.

- Key applications: Cement plants, steel mills, woodworking facilities, food processing, pharmaceuticals, mining, and chemical production, and many more

If you’re managing an industrial facility, you know the challenges. Dust isn’t just a nuisance—it’s a health hazard, an explosion risk, and a regulatory compliance issue. The EPA and OSHA have strict standards, and your workers deserve clean air.

Baghouses solve this problem. They’ve been the workhorse of industrial dust collection since the late 1970s, when high-temperature fabrics made them practical for demanding applications. Today, they handle everything from fine pharmaceutical powders to abrasive cement dust at temperatures up to 550°F (or higher with specialty fabrics).

The beauty of baghouse technology is its simplicity and versatility. Whether you’re dealing with heavy dust loads, sticky particulates, or high-temperature processes, there’s likely a baghouse solution that fits. But choosing the right system requires understanding how it works, what options are available, and how to maintain it for maximum efficiency.

This guide will walk you through everything you need to know—from basic operation to advanced design considerations—so you can make informed decisions about your facility’s air quality control.

What Is a Baghouse and How Does It Work?

Picture a giant vacuum cleaner for your factory—that’s essentially what a baghouse dust collector is, though calling it that doesn’t quite do justice to its engineering sophistication. These air pollution control devices are designed to capture and remove airborne dust and particulate matter from industrial processes, keeping your facility compliant and your workers safe.

The filtration process is surprisingly simple. A fan or blower pulls contaminated air into the baghouse housing, where it encounters filter media in the form of bags or cartridges. As dirty air passes through these porous fabric filters, dust particles are trapped on the surface, while clean air continues through and exits the system.

Here’s where it gets interesting: those filters don’t work alone for long. As dust accumulates on their surfaces, it forms a dust cake. You might think this buildup would be a problem, but it’s actually a feature. This dust cake acts as a secondary filter, more effective than the filter fabric itself, capturing particles so fine they would otherwise slip through. That’s why baghouse dust collectors routinely achieve collection efficiencies of 99% or better, even with microscopic particles.

Of course, you can’t let that dust cake build up forever. As it thickens, it creates resistance to airflow—what we call pressure drop. This is a critical measurement because too much pressure drop means your system has to work harder, wasting energy and reducing efficiency. That’s where the cleaning system comes in. It periodically knocks or blasts accumulated dust off the filters, allowing it to fall into a collection hopper below while the filters resume operation.

Unlike household vacuums that require new filters every few months, baghouses are engineered for continuous operation. Their built-in cleaning mechanisms automatically regenerate the filter media, keeping your air clean 24/7 without requiring constant filter replacement. If you want to explore the fundamentals in more depth, check out our article on What is a Baghouse?. For an even deeper look at how these systems separate dust from air so effectively, read The Baghouse Insider: Separating Dust from Air.

Core Components of a Baghouse System

Understanding how baghouse dust collectors work means getting familiar with their essential parts. Each component has a specific job, and they all work together to keep your facility’s air clean.

The filter media—those fabric bags and cartridges we’ve been talking about—are the heart of the system. These long, cylindrical tubes are where the actual dust collection happens. The fabric choice matters enormously because different dusts, temperatures, and chemical environments require different materials. You wouldn’t use the same fabric for a hot cement kiln as you would for a cool woodworking shop.

Filter bags need support, which is where filter cages come in. These metal frames slide into each bag to prevent collapse under pressure or during cleaning cycles. Think of them as the skeleton that gives the bag its shape. Filter cartridges are self-supporting.

The fan or blower is your system’s engine, creating airflow that pulls in contaminated air and pushes clean air out. Getting the fan sizing right is crucial—too weak, and you won’t move enough air; too powerful, and you’ll damage your bags or waste energy.

We’ve already mentioned the cleaning system, but it’s worth emphasizing how vital this component is. Whether it uses mechanical shaking, reverse air, or compressed-air pulses, this mechanism keeps your filters operating efficiently by periodically removing accumulated dust.

At the bottom of every baghouse sits the hopper, a pyramidal or trough-shaped collection area where dislodged dust falls after cleaning. Below that, a discharge unit—usually a rotary valve or screw conveyor—removes the collected dust for disposal or recovery.

The tubesheet is a horizontal plate that serves dual functions: it holds the filter bags in place and separates the dirty side of the system from the clean side. Only filtered air gets past this barrier.

Finally, the housing encases everything, protecting internal components from weather and directing airflow where it needs to go. It’s the shell that holds this sophisticated filtration machine together.

Each of these components has been refined over decades of industrial use. At Sly, we’ve been perfecting baghouse design since 1902, when we built the first cloth-type dust collector. That experience shows in how our systems integrate these components into reliable, efficient air pollution control solutions that keep your operations running smoothly and your air clean.

Types of Baghouses and Their Cleaning Mechanisms

When you’re choosing a baghouse dust collector for your facility, one of the most important decisions you’ll make is selecting the right cleaning mechanism. Think of it this way: the filter bags do the heavy lifting of capturing dust, but they need a reliable way to shake off the accumulated dust cake so they can keep working efficiently. The cleaning system enables that.

The three main cleaning methods—mechanical shaker, reverse air, and pulse jet—each have distinct characteristics and ideal use cases. Some are gentle and steady, others are quick and powerful. The right choice depends on your specific dust characteristics, operational needs, and budget.

Let’s break down how each type works and where they shine.

Mechanical Shaker

The mechanical shaker is the elder statesman of baghouse cleaning systems. It’s straightforward and gets the job done with good old-fashioned mechanical action. In these systems, dust collects on the inside of the filter bags. When it’s time to clean, the system shuts down the airflow to that compartment—this is called off-line cleaning—and a motor physically shakes the bags to knock the dust loose.

The simplicity of this design means you’ll face a low capital cost upfront, which can be attractive if you’re working within a tight budget. The straightforward mechanics also make these systems easier to understand and operate. However, because you need to take compartments offline for cleaning, they work best for intermittent operation rather than continuous processes.

Mechanical motion causes wear and tear on the bags and moving parts, so you can expect higher maintenance requirements than with other systems. But if you’re dealing with non-sticky dusts in applications like minerals processing, a mechanical shaker baghouse can be a reliable workhorse. They handle abrasive materials well and don’t require a compressed-air system.

Reverse Air

If the mechanical shaker is the straightforward older sibling, the reverse air baghouse is the gentler, more sophisticated one. These systems collect dust on the outside of the bags, but they clean using a much kinder approach. Instead of shaking, they use low-pressure, high-volume air blown in the opposite direction of normal airflow.

Here’s how it works: A continuously rotating arm with integral Venturis directs cleaning air into the filters’ interior. An internally mounted centrifugal pressure blower supplies this cleaning air.

The resulting gentle reverse airflow slightly inflates the bags. This subtle movement fractures the dust cake, allowing it to fall into the hopper. Because the cleaning action is less aggressive, filter wear is reduced, and bag life is typically extended—meaning longer service intervals before replacement is required.

The reverse air design really shines when you’re working with high-temperature fabrics like fiberglass. These materials can be brittle and wouldn’t survive the aggressive shaking of a mechanical system, but they handle reverse air cleaning beautifully. The system is compartmentalized, meaning you can clean one section while others keep running, which is perfect for continuous operations.

You’ll find reverse air baghouses in facilities where processes run at elevated temperatures or where dust is combustible and requires careful handling. Our TubeJet Baghouse Dust Collectors feature advanced baghouse technology and can be customized for various cleaning methods, including reverse-air systems.

Pulse Jet

Now we’re talking about the most popular kid on the block. The pulse jet baghouse has become the most common type of dust collector in modern industry, and for good reason. It’s efficient, versatile, and keeps running without interruption.

Here’s what makes it different: An exhaust fan draws ventilation air, creating a negative pressure environment within the baghouse, causing dust to collect on the outside of the filter media. Filter bags are supported by internal metal cages, while cartridge filters are self-supported.

Above the filters, a compressed-air manifold with strategically placed nozzles delivers short, high-pressure, low-volume bursts of air directly into the bags. These pulses generate a shockwave that rapidly deflects the filters outward, dislodging the dust cake and causing it to fall into the hopper below.

The beauty of pulse jet systems is continuous operation. Unlike shaker air systems that require shutting down compartments for cleaning, pulse-jet baghouses clean on the fly. They can pulse individual rows of filters while the rest of the system keeps filtering. This means no downtime and consistent performance.

Because cleaning is so effective, pulse-jet systems can operate at higher air-to-cloth ratios. In plain English, that means you get more filtering capacity in a smaller footprint. You need less filter area to handle the same amount of dirty air, resulting in a more compact unit and often lower overall costs, despite the need for compressed air.

The high collection efficiency of pulse jet systems—typically 99% or better—combined with their versatility, makes them suitable for everything from cement plants to pharmaceutical facilities. They handle sticky dusts, abrasive materials, and varying dust loads with equal confidence.

Want to dive deeper into how this robust cleaning mechanism works? Check out The Baghouse Insider: Separating Dust from Air for more about the pulse-jet baghouse and why it has become the go-to choice for so many industrial applications.

The efficiency of pulse-jet cleaning enables baghouse dust collectors to achieve much higher volumetric throughput per unit filter area than shaking and reverse-air systems. That’s why you’ll find them working hard in facilities across the world.

Designing for Performance: Key Factors and Filter Media

Getting a baghouse dust collector right isn’t just about picking something off the shelf. It’s about understanding your specific process and designing a system that will perform reliably for years to come. At Sly, LLC, we’ve been doing this since 1902, and we know that every detail matters when it comes to delivering the cleanest air possible.

The performance of your baghouse depends on a careful balance of engineering principles and real-world application needs. You need to consider system sizing to handle your airflow requirements, operational efficiency to keep costs down, and the specific characteristics of the dust you’re collecting. That last point is crucial—dust isn’t just dust. Particle size, abrasiveness, temperature, moisture content, and chemical composition all play major roles in how your system should be designed.

Get any of these factors wrong, and you’re looking at premature filter failure, reduced efficiency, and costly downtime. Nobody wants that. That’s why understanding Dust Collector Sizing: What Size Do You Need? is such an important starting point.

Key Considerations for Designing Baghouse Dust Collectors

When we engineer a baghouse, we’re looking at the complete picture of your operation. Here are the critical variables that determine whether your system will be a workhorse or a headache:

Air-to-cloth ratio is perhaps the most fundamental parameter. It’s the air volume flowing through your baghouse divided by the total filter area. Think of it as the speed at which air passes through your filters. Too high, and you’ll wear out your bags quickly while getting poor collection efficiency. Too low, and you’re spending more than necessary on a larger system. Getting this ratio right is essential for both efficient filtration and reasonable bag life.

Pressure drop monitoring is your baghouse’s vital sign. As dust accumulates on your filter bags, the resistance to airflow increases—that’s your differential pressure, ΔP. Monitoring this metric tells you when cleaning cycles should occur, when filters might clog, and when issues are developing before they become expensive failures.

Filter drag is closely related to pressure drop. It’s the resistance created by that dust cake building up on your filter surface. While we want some dust cake for optimal filtration, too much indicates it’s time to clean. This balance between cake buildup and cleaning is where efficiency lives.

Inlet design might not sound exciting, but it’s absolutely critical. How dirty air enters your baghouse affects everything downstream. A well-designed inlet—often with an expanded diffuser—prevents turbulence in the hopper that can re-entrain dust. It creates what we call a quiescent free-board zone, which is just a fancy way of saying “a calm area where dust can settle peacefully.” This reduces filter abrasion and improves overall performance. We’ve written about different approaches in High vs Low Inlet Baghouses if you’re curious about the options.

Interstitial velocity refers to the upward speed of air in the space between your filter bags. Keep this too high, and the dust you just cleaned off the bags gets swept right back up and redeposited. It’s like trying to sweep your floor in a windstorm. We design systems to keep interstitial velocity low enough that cleaned dust actually reaches the hopper.

All these factors work together to ensure your baghouse dust collector isn’t just compliant with regulations, but truly optimized for long-term, cost-effective operation.

Choosing the Right Filter Media for Your Baghouse Dust Collectors

If the baghouse is the heart of your dust collection system, the filter media is the heart valve—absolutely critical, and when it fails, everything fails. Choosing the right filter bags directly influences your collection efficiency, how long your system runs between maintenance, and your overall operating costs.

Here’s the reality: there’s no universal “best” filter media. The right choice depends entirely on what you’re filtering and under what conditions. Pick the wrong material, and you’ll be replacing bags constantly, watching efficiency drop, and spending far more on maintenance than you should. Our article A Deep Dive into Filter Bags for Dust Collection Systems covers this topic extensively.

Filter bags are typically long cylindrical tubes, ranging from 2 to 12 inches in diameter and 3 to 40 feet in length. The material matters enormously. Polyester is economical and well-suited for most general applications, but it has temperature and chemical limitations. Aramid (like Nomex) can handle higher temperatures and is more durable. Fiberglass is your go-to for high-temperature applications, but it can be brittle. P84 offers excellent chemical resistance and performs well in challenging conditions. PTFE is the premium choice for the most demanding applications, including high-temperature environments and aggressive chemicals.

Here’s how these common materials compare:

| Filter Media Type | Temperature Rating (Max Continuous) | Acid Resistance | Alkali Resistance | Typical Cost | Key Characteristics |

|---|---|---|---|---|---|

| Polyester | 275°F (135°C) | Fair | Good | Low | Most economical; good for general applications; moisture resistant |

| Aramid | 400°F (204°C) | Fair | Good | Medium | Excellent abrasion resistance; good strength |

| Fiberglass | 500°F (260°C) | Excellent | Poor | Medium | High temperature capability; can be brittle; needs careful handling |

| P84 | 500°F (260°C) | Good | Fair | High | Excellent fine particle capture; good chemical resistance |

| PTFE | 500°F+ (260°C+) | Excellent | Excellent | Very High | Superior chemical resistance; excellent cake release; long life |

Beyond the base material, you also need to consider the fabric construction. Woven fabrics are durable but have larger openings between fibers. Felted or needled media provides better filtration of fine particles. Membrane filters add a thin layer (often ePTFE) to the surface, which dramatically improves filtration efficiency and makes cleaning easier—our article, “When Should You Use an ePTFE Membrane Filter Bag?,” explains when this premium option makes sense. Cartridge (or pleated) filters pack more filter area into less space, allowing for more compact designs.

The bottom line? Filter media selection isn’t something to guess at. It requires understanding your dust characteristics, operating temperatures, chemical exposure, and moisture levels. Get it right, and your baghouse dust collectors will run efficiently for years. Get it wrong, and you’ll know it quickly—and expensively.