Why Pulse Jet Filter Cleaning Matters for Industrial Air Quality

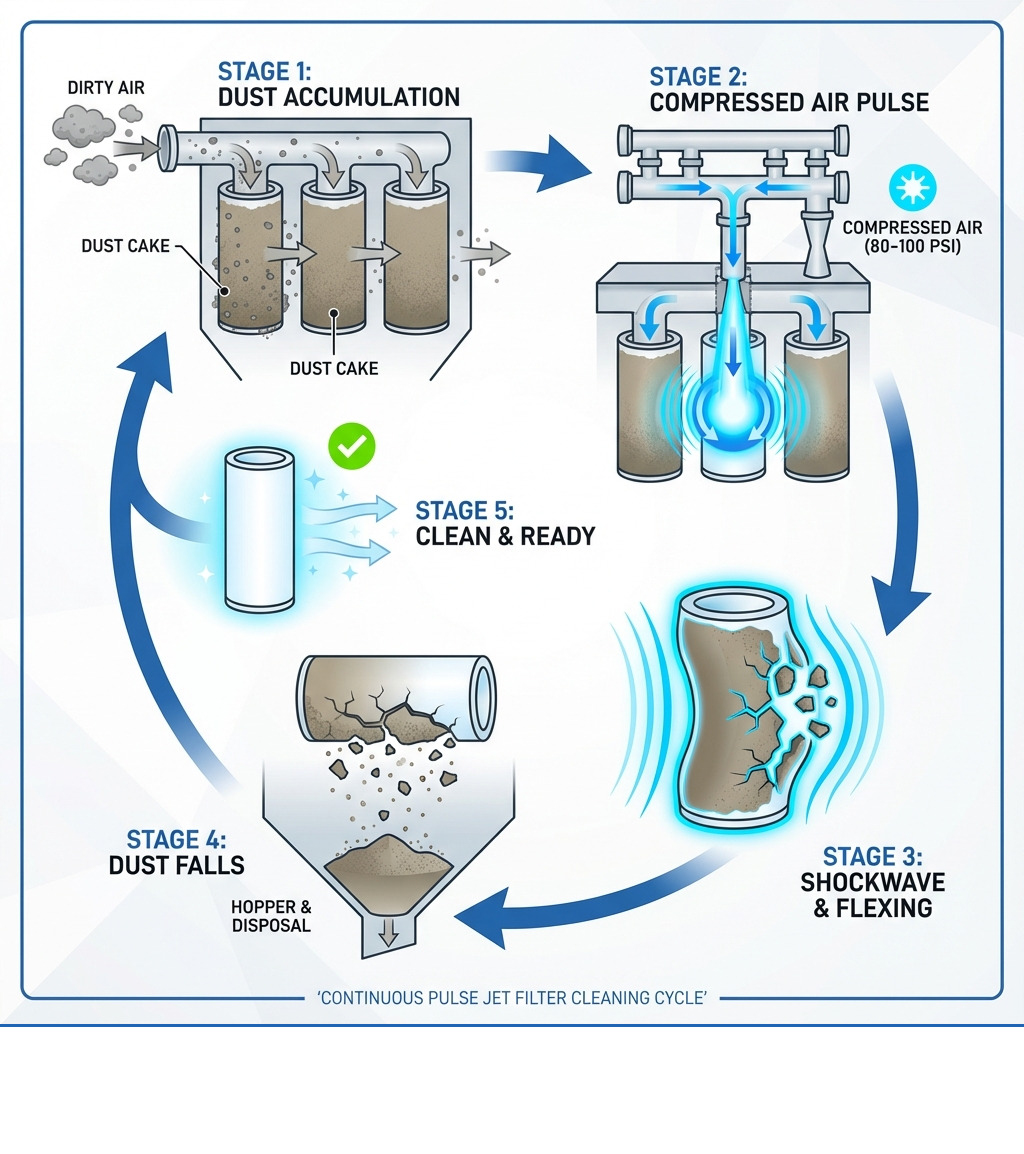

Pulse jet filter cleaning is a method that uses short bursts of compressed air to remove accumulated dust from baghouse filters without stopping your production line. Here’s how it works:

- Dust builds up on filter surfaces as clean air passes through media

- Compressed air pulses (80-100 PSI) blast through the filters in reverse

- The shockwave flexes the filter media, breaking the dust cake loose

- Dust falls into collection hoppers below for disposal

- Clean filters resume normal operation immediately

If you manage an industrial facility, you know that dust isn’t just a nuisance—it’s a compliance issue, an efficiency problem, and a safety hazard. Your baghouse dust collector works around the clock to capture particulate matter, but those filters can’t stay clean on their own.

Dirty filters mean higher energy costs, reduced airflow, and potential equipment failure. That’s where pulse jet technology comes in. This automated cleaning system keeps your filters operating at peak performance without shutting down your operation.

The beauty of pulse jet cleaning is its simplicity: compressed air does the heavy lifting while your system keeps running. No manual filter shaking, no production downtime, no workers exposed to hazardous dust. Whether you’re running a timer-based schedule or an on-demand system that responds to actual pressure readings, understanding this process helps you optimize performance and extend filter life.

How a Pulse Jet Dust Collector Works

At Sly, LLC, we’ve been pioneering industrial air pollution control since 1902, and we know a thing or two about keeping industrial air clean. Our baghouses are at the heart of many operations across the world, and the pulse jet filter cleaning mechanism is what keeps them running smoothly.

Imagine your facility generates fine particulate matter—sawdust from a woodworking shop, cement dust from a manufacturing plant, or fine powders from a chemical process. This airborne dust is drawn into your pulse jet dust collector, which is essentially a large, specialized air filter.

The dirty air enters a chamber called the dirty air plenum. From there, it’s forced through a series of fabric filter bags or cartridges. As the air passes through the filter media, the dust particles are trapped on the outside surface of the bags, while the now-clean air passes through to the clean air plenum and is exhausted back into the atmosphere or recirculated within the plant.

Over time, this trapped dust forms a layer, often called a dust cake, on the filter surface. This dust cake is actually beneficial up to a point, as it aids in further filtration, capturing even finer particles. However, if it gets too thick, it starts to restrict airflow, causing a rise in differential pressure across the filters. This is where our hero, the pulse jet system, steps in.

The collected dust eventually falls into a hopper at the bottom of the collector, ready for periodic removal and disposal.

The Filtration Stage

The primary goal of any dust collector is to separate dust from air. In a pulse jet system, this happens during the filtration stage. As dirty air enters the collector, its velocity often decreases, allowing heavier particles to fall directly into the hopper. The remaining lighter particles are then carried upwards towards the filter elements.

As the air flows through the filter media—whether it’s a woven fabric bag or a pleated cartridge—the dust particles are captured. The filter’s porosity and the fiber structure determine its efficiency. Initially, the clean filter allows air to pass through relatively easily. As dust accumulates, a permeable layer forms, which actually improves filtration efficiency by acting as an additional filter layer. This is the “dust cake” we mentioned.

However, this growing dust cake also increases the resistance to airflow. Think of it like trying to breathe through a progressively thicker cloth. The system’s fans have to work harder, consuming more energy, and the overall airflow through your facility’s processes can decrease, impacting production efficiency. This is why effective pulse jet filter cleaning is so critical.

The Role of Key Components

To understand how the cleaning works, let’s look at the key players within the pulse jet system:

- Tube Sheet: This is a perforated metal plate that separates the dirty air plenum from the clean air plenum. The filter bags or cartridges are mounted into the holes in the tube sheet, creating a seal that ensures all dirty air passes through the filters, not around them.

- Venturis: These are conical-shaped nozzles located at the top of each filter bag, extending slightly into the bag. When the compressed air pulse fires, the venturi helps to accelerate the air and distribute the shockwave evenly down the length of the filter bag. This maximizes the cleaning effect.

- Blowpipes (or Manifolds): These are horizontal pipes positioned above the rows of filter bags. Each blowpipe has a series of nozzles directly above the venturis. They deliver the high-pressure compressed air pulses to specific rows of filters.

- Filter Cages: For filter bags, these internal wire cages provide structural support, preventing the bags from collapsing under the differential pressure during filtration and ensuring they flex outward properly during cleaning. Cartridge filters are typically self-supporting.

- Solenoid and Diaphragm Valves: These are the brains and brawn of the cleaning cycle. The solenoid valve is an electrically actuated valve that, when energized by the system’s controller, opens to release a small burst of air. This pilot air then actuates the much larger diaphragm valve, which rapidly opens to release the high-pressure compressed air from the blowpipe into the filter elements. It’s a rapid, powerful sequence.

The Step-by-Step Pulse Jet Filter Cleaning Process

Now that we know the components, let’s dive into the action! The pulse jet filter cleaning process is a marvel of automated efficiency. It uses short, powerful blasts of compressed air to maintain optimal filtration, often without interrupting the dust collection process. This means your operations can keep running smoothly, minimizing downtime.

The core idea is to create a momentary, intense shockwave that travels down the inside of the filter bag or cartridge. This shockwave causes the filter media to flex and expand rapidly, breaking the accumulated dust cake off the surface. Gravity then does the rest, pulling the dislodged dust down into the hopper below.

There are primarily two ways to initiate this cleaning: on-demand cleaning (triggered by the system’s performance) or timer-based cleaning (triggered at set intervals). We’ll explore the benefits of each later, but both rely on the same fundamental steps.

Step 1: Monitoring Dust Accumulation

The cleaning process doesn’t just happen randomly; it’s a response to the system’s needs. The most common way we monitor this need is through a differential pressure gauge or transmitter. This device measures the pressure difference between the dirty air plenum (before the filters) and the clean air plenum (after the filters).

As dust accumulates on the filters, this pressure difference increases. The system’s controller is programmed with setpoints—a low setpoint (indicating clean filters) and a high setpoint (indicating filters are getting dirty and need cleaning).

Maintaining an optimal dust cake thickness is crucial. Too thin, and you’re over-cleaning, wasting compressed air and potentially reducing filter life. Too thick, and you’re experiencing excessive airflow restriction, high energy consumption, and reduced system efficiency. The controller constantly reads the differential pressure, acting as the watchful eye of your dust collector.

Step 2: Triggering the Cleaning Cycle

Once the differential pressure reaches the high setpoint, or if a pre-set time interval has passed, the cleaning cycle is triggered.

- On-Demand Controller: In this sophisticated setup, the controller directly monitors the differential pressure. When the pressure reaches the programmed high limit, it signals the cleaning system to begin. This ensures cleaning only happens when necessary, optimizing compressed air usage and filter lifespan.

- Timer Board: For simpler systems, a timer board initiates the cleaning cycle at regular, pre-programmed intervals, regardless of the actual dust load. While less efficient, it’s a reliable method for many applications.

Regardless of the trigger, the next action is the activation of the solenoid valve. The controller sends an electrical signal, causing the solenoid to open for a fraction of a second. This releases a small burst of pilot air. This pilot air then travels to the diaphragm valve, which is a much larger valve designed to handle the high volume of compressed air needed for the pulse. The pilot air pressure causes the diaphragm valve to snap open, allowing a powerful burst of compressed air to flow from the air header tank, through the blowpipe, and into the venturis above a row of filters.

Step 3: Dislodging the Dust Cake

This is the dramatic part of the pulse jet filter cleaning process! As the diaphragm valve opens, a sudden, high-pressure blast of compressed air—typically between 80-100 PSI (pounds per square inch)—rushes down the blowpipe. This air is directed into the venturis at the top of the filter bags or cartridges.

The venturi effect helps to accelerate this air, creating a powerful shockwave that travels rapidly down the inside of the filter element. This shockwave causes the filter media to momentarily flex and expand outwards. This rapid flexing action effectively breaks the bond between the accumulated dust cake and the filter surface.

Once dislodged, gravity takes over. The dust cake, now detached, falls from the filters into the dust collection hopper at the bottom of the baghouse. From there, it’s typically discharged via a rotary airlock or screw conveyor for disposal. The entire pulse lasts only a fraction of a second, and it’s usually sequenced so that only a small section or row of filters is cleaned at a time, allowing the rest of the collector to continue filtering dirty air without interruption. This ensures continuous operation and minimal impact on your facility’s air quality.

Optimizing Your System for Peak Performance

A well-maintained pulse jet filter cleaning system isn’t just about compliance; it’s about efficiency and longevity. Optimizing your system means saving money on energy consumption, extending filter lifespan, ensuring compressed air quality, and adhering to smart maintenance schedules. At Sly, LLC, we understand that reliability and no-compromise solutions are key to the cleanest air possible.

When your pulse jet system is optimized, it operates like a finely tuned instrument. Filters last longer, energy bills are lower, and you face fewer unexpected shutdowns. It’s a win-win for your bottom line and your environmental footprint.

| Cleaning Method | Initial Cost | Energy Consumption | Filter Life | System Stability |

|---|---|---|---|---|

| On-Demand | Higher | Lower | Longer | More Stable |

| Timer-Based | Lower | Higher | Shorter | Less Stable |

Fine-Tuning Pulse Pressure and Duration

Getting the pulse just right is a delicate balance.

- Over-cleaning risks: If the compressed air pulse is too strong or too frequent, it can lead to over-cleaning. This means you’re wasting valuable compressed air, which is an expensive utility. Even worse, excessive flexing of the filter media can accelerate wear and tear, leading to premature filter failure. This results in higher replacement costs and increased maintenance downtime. It’s like scrubbing a dish too hard; you might get it clean, but you’ll scratch it in the process.

- Under-cleaning consequences: On the flip side, if the pulse is too weak or too infrequent, you’ll experience under-cleaning. The dust cake won’t be adequately dislodged, leading to an ever-thickening layer of dust on the filters. This causes a persistently high differential pressure, increased fan energy consumption, reduced airflow, and eventually, “blinding” of the filters, where they become so clogged they can no longer filter effectively.

The key is to follow manufacturer specifications for your specific filter media and dust type. Our experts at Sly, LLC can help you determine the ideal pulse duration adjustment and pressure for your unique application. Generally, a short, sharp pulse is more effective than a long, drawn-out one. Most systems operate with pulse durations measured in milliseconds.

The Benefits of On-Demand Cleaning

While timer-based cleaning has its place, we highly recommend on-demand cleaning whenever possible. It’s a smarter, more efficient approach that pays dividends.

- Energy Savings: The most significant benefit is reduced compressed air consumption. An on-demand system only cleans when necessary, reacting to the actual dust load and differential pressure. This can lead to substantial energy savings over time, as compressed air generation is one of the most energy-intensive processes in many industrial facilities.

- Reduced Mechanical Stress: By avoiding unnecessary cleaning cycles, on-demand systems minimize the mechanical stress on your filter media, blowpipes, and valves. This directly translates to extended filter life, meaning fewer filter replacements and less labor associated with change-outs.

- Extended Filter Life: Because filters are not subjected to constant, unwarranted flexing, they simply last longer. This reduces your operational costs and environmental impact.

- Stable System Pressure: On-demand cleaning helps maintain a more consistent differential pressure across the filters, leading to more stable system pressure and airflow throughout your dust collection system. This contributes to more consistent process performance in your facility.

For more insights into keeping your dust collector running optimally, explore resources on dust collector maintenance best practices.

Best Practices for an Effective Pulse Jet Filter Cleaning

To ensure your pulse jet filter cleaning system performs at its peak, consider these best practices:

- Clean, Dry Compressed Air: This is non-negotiable. Moisture and oil in your compressed air supply can severely damage diaphragm valves, corrode internal components, and cause dust to “mud up” on filter surfaces, leading to blinding. Invest in high-quality air dryers and filters for your compressed air system.

- Regular Valve Inspection: Your solenoid and diaphragm valves are critical. Regularly inspect them for signs of wear, leaks, or sluggish operation. A failing valve can lead to ineffective cleaning of entire rows of filters.

- Leak Detection: Even small leaks in your baghouse can compromise efficiency and lead to dust emissions. Regular visual inspections and the use of fluorescent leak detection powder (which glows under UV light) can help identify torn bags, faulty seals, or pinholes.

- Controller Calibration: Ensure your differential pressure gauge and controller are regularly calibrated. An inaccurate reading can lead to either over-cleaning or under-cleaning, both of which are detrimental to system performance and filter life.

Common Problems and Troubleshooting

Even the most robust pulse jet filter cleaning systems can encounter issues. Recognizing the symptoms and knowing how to troubleshoot them can save you time, money, and headaches. Problems often manifest as visible emissions from the stack, a persistently high pressure drop across the filters, reduced airflow at pickup points, or simply ineffective cleaning. Addressing these issues promptly is not just about efficiency; it’s also about maintaining compliance and ensuring worker safety, especially when dealing with combustible dust. OSHA provides valuable guidance on combustible dust control.

Problem: High Differential Pressure

A consistently high differential pressure reading is a clear indicator that something is amiss with your pulse jet filter cleaning. It means air isn’t flowing easily through your filters, and the fan is working harder than it should.

- Blinded Filters: This is the most common culprit. Filters become “blinded” when the dust cake adheres too strongly or becomes saturated with moisture or oil, making it impermeable. This can be caused by improper cleaning parameters (too weak a pulse), incorrect filter media for the application, or contaminants in the compressed air.

- Moisture in the System: If your compressed air isn’t dry, moisture can enter the baghouse. When this combines with dust, it creates a sticky, mud-like substance that can permanently blind filters. This is especially problematic in humid environments.

- Incorrect Pulse Pressure: If the pulse pressure is too low, it won’t effectively dislodge the dust cake. Check your compressed air supply pressure and ensure your diaphragm valves are opening fully.

- Hopper Bridging: Sometimes, the dust collected in the hopper can “bridge” or arch over the discharge opening, preventing it from exiting. This can cause dust to back up into the filter area, leading to high differential pressure and re-entrainment of dust onto freshly cleaned filters.

Troubleshooting Your Pulse Jet Filter Cleaning System for Leaks

Leaks in a baghouse are a serious concern, leading to dust emissions, reduced efficiency, and potential regulatory fines.

- Torn or Damaged Filters: The most common source of leaks. Filters can tear due to abrasion from dust, improper installation, chemical attack, or excessive mechanical stress from over-cleaning.

- Improper Filter Installation: If filters aren’t seated correctly in the tubesheet, or if their clamps/gaskets aren’t sealed properly, dirty air can bypass the filter media altogether.

- Leaky Welds or Seals: Over time, structural welds or gasketed access doors can develop leaks, allowing dust to escape.

- Fluorescent Leak Detection Powder: This is an invaluable tool. Introduce the powder into the dirty air stream. The powder will collect on the outside of the filters. After a short run time, shut down the collector and inspect the clean air plenum with a UV light. Any glowing areas indicate a leak, pinpointing exactly where a filter is torn or a seal is compromised.

Problem: Weak or No Pulse

If your filters aren’t getting cleaned, the problem might lie with the pulsing mechanism itself.

- Low Compressed Air Supply: This is often overlooked. Ensure your plant’s compressed air system can consistently deliver the required pressure and volume to the baghouse. Check for blockages or leaks in the air lines leading to the collector.

- Diaphragm Valve Failure: The diaphragm valve is a wear item. Over time, the rubber diaphragm can stiffen, tear, or become clogged, preventing it from opening fully or at all. Inspect these valves regularly.

- Solenoid Malfunction: The small solenoid valve acts as the pilot for the diaphragm valve. If it fails (e.g., electrical coil burnout, clogged orifice), the diaphragm valve won’t receive the signal to open.

- Frozen Air Lines: In colder climates, moisture in compressed air lines can freeze, blocking the flow to solenoid or diaphragm valves. This underscores the importance of dry compressed air.

Frequently Asked Questions about Pulse Jet Filter Cleaning

We often hear similar questions from our clients about their pulse jet filter cleaning systems. Here are some of the most common ones, along with our expert answers.

How often should pulse jet filters be cleaned?

The ideal cleaning frequency isn’t a one-size-fits-all answer; it depends on several factors:

- Dust Loading: Facilities with high dust concentrations will naturally require more frequent cleaning than those with lighter dust loads.

- Type of Dust: Some dusts are stickier or more abrasive than others, influencing how quickly they build up and how easily they’re dislodged.

- Filter Media: Different filter fabrics or cartridge materials have varying dust release characteristics.

- Desired Differential Pressure: The cleaning frequency should be set to maintain the differential pressure within the manufacturer’s recommended operating range.

For optimal performance, we generally recommend using an on-demand cleaning system that triggers cleaning based on differential pressure. This ensures filters are cleaned only when necessary, saving compressed air and extending filter life. If using a timer-based system, start with the manufacturer’s recommendation and adjust based on observed differential pressure and filter condition.

What is the ideal compressed air pressure for a pulse jet system?

Most pulse jet filter cleaning systems operate with a compressed air pressure between 80 and 100 PSI (pounds per square inch) at the header tank. However, the exact ideal pressure can vary based on:

- Baghouse Design: Different manufacturers and designs may have specific requirements.

- Filter Length: Taller filters often require slightly higher pressures to ensure the shockwave travels effectively down the entire length of the bag.

- Dust Characteristics: Very dense or sticky dusts might benefit from a slightly higher pressure, while lighter, easily dislodged dusts might perform well at lower pressures.

It’s crucial to consult your baghouse’s operation and maintenance manual for the manufacturer’s recommended pressure range. Operating significantly below this range will result in ineffective cleaning, while operating too high can lead to over-cleaning and premature filter wear. Always ensure your compressed air supply is clean, dry, and free of oil.

Can you clean pulse jet filters while the dust collector is online?

Yes, absolutely! This is one of the primary advantages and defining features of pulse jet filter cleaning technology. Unlike older shaker-style or reverse-air collectors that often require the dust collector to be taken offline (or a compartment isolated) for cleaning, pulse jet systems are designed for continuous, online cleaning.

The cleaning pulses are very short (milliseconds) and are typically sequenced across rows or small groups of filters. This means that while a small section of filters is being cleaned, the vast majority of the filters remain actively engaged in the filtration process. This enables uninterrupted production, a major benefit for industrial facilities seeking to maximize uptime and efficiency. This capability is a cornerstone of the reliable, no-compromise solutions we provide at Sly, LLC.

Conclusion

Understanding pulse jet filter cleaning is not just about knowing how a machine works; it’s about mastering a critical component of your facility’s operational efficiency, air quality, and regulatory compliance. We’ve walked through the intricate dance of dirty air, dust cake formation, and the powerful, precise bursts of compressed air that keep your filters clean and your systems running.

From the initial filtration stage to the fine-tuning of pulse pressure, every element plays a vital role in ensuring optimal performance. We’ve seen how on-demand cleaning can lead to significant energy savings and extended filter life, and how vigilant troubleshooting can prevent minor hiccups from becoming major headaches.

At Sly, LLC, with our roots stretching back to 1902, we pride ourselves on delivering solutions that ensure the cleanest air possible. Our expertise in designing and manufacturing high-quality industrial air pollution control systems, including advanced baghouses, enables us to understand the nuances of effective dust management. By implementing the best practices we’ve discussed, you’re not just cleaning filters; you’re investing in the longevity of your equipment, the health of your workforce, and the sustainability of your operations.

Ready to optimize your air quality control? Explore our high-efficiency baghouse dust collectors and find out how our no-compromise solutions can benefit your facility.