Why Baghouse Dust Collector Filters Matter for Your Facility

Baghouse dust collector filters are the primary components that capture and remove dust and particulate matter from industrial air streams. These fabric filter bags—made from materials like polyester, aramid, or PTFE—trap dust on their surface while allowing clean air to pass through, achieving collection efficiencies greater than 99 percent.

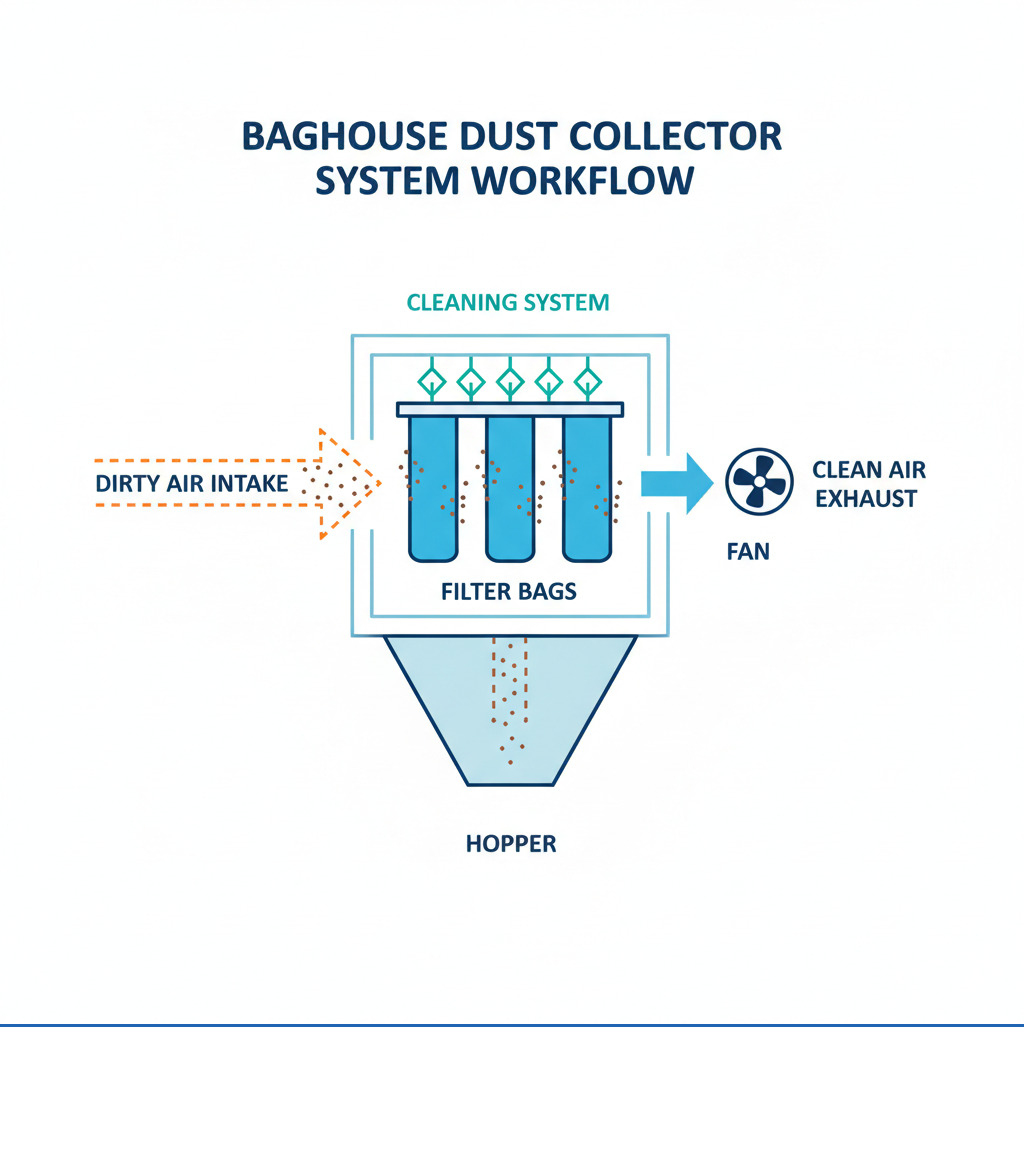

Key components of a baghouse dust collection system include:

- Filter bags – Fabric tubes that capture dust particles

- Filter cages – Wire support structures that hold bags in shape

- Cleaning system – Pulse-jet, reverse-air, or shaker mechanisms that remove accumulated dust

- Housing – Metal enclosure containing all components

- Hopper – Collection chamber for removed dust

- Fan/blower – Creates airflow through the system

- Valves – Control compressed air for cleaning cycles

If you’re managing a facility with challenging dust environments, understanding these components helps you maintain clean air, stay compliant with EPA regulations, and avoid costly downtime. The wrong filter material can lead to premature failure, excessive emissions, and damaged equipment. The right selection based on temperature, dust properties, and chemical resistance extends filter life two to three times longer than standard options.

Most baghouse systems work through a simple cycle: dirty air enters the housing, passes through fabric filter bags where dust accumulates on the surface, and clean air exits through the outlet. A cleaning system periodically removes the dust cake, allowing the filters to continue operating efficiently.

The Heart of the System: Understanding Baghouse Dust Collector Filters

Baghouse dust collector filters are the heart of your dust collection system. These engineered fabric filters capture microscopic particles while allowing clean air to pass through. When dust-laden air enters the baghouse, particles accumulate on the filter surface, forming a “dust cake.” This dust cake improves filtration, helping to trap even finer particles and achieve collection efficiencies greater than 99 percent. The filter media’s job is to balance particle capture with airflow, which is key to an effective system. You can explore our complete range of Dry Dust Collector Filter Bags to see the variety available.

Different Types of Baghouse Filter Media

Selecting the right filter media is critical. The operating temperature, chemical exposure, and dust characteristics all determine the correct material for your application.

Polyester is the most common filter material. It handles temperatures up to 275°F, resists acids well, and offers excellent value. Our Polyester PE filters are versatile workhorses, but they can struggle in moist heat where hydrolysis can break down the fibers.

For higher temperatures, Aramid (e.g., Nomex) handles continuous temperatures up to 400°F. It provides good resistance to acids and alkalis in dry conditions and has excellent abrasion resistance, making it ideal for rougher dust.

For demanding environments, P-84 polyimide felt performs well at temperatures up to 460°F. It excels at capturing fine particulate matter, making it a top choice where collection efficiency is critical. Learn more in our guide on Efficiency and Durability: High-Temperature Dust Collector Bags.

PTFE (Teflon) is a premium filter material with temperature ratings up to 500°F and exceptional chemical resistance. Its smooth surface allows for easy dust cake release, improving cleaning and extending filter life, though it has a higher initial cost.

Fiberglass also has a 500°F rating and good acid resistance. However, it is more brittle than felt materials and can be damaged more easily during installation or cleaning.

Filter Media Construction and Finishes

Filter bag construction significantly impacts performance. Traditional needle punch felts are created by tangling fibers with barbed needles. This process can create an irregular surface where fine dust particles embed deeply into the fabric, making cleaning difficult.

Specialty finishes improve filter performance. Oleophobic treatments are essential for greasy particulate, as they repel oil and moisture to prevent the filter surface from blinding. Anti-static treatments are critical for safety in combustible dust applications; they prevent static charge buildup, reducing spark risks and improving dust release during cleaning. PTFE membrane lamination adds a surface filtration layer that prevents dust from entering the base fabric. This results in superior dust cake release, lower pressure drop, and high efficiency for fine particulate, extending service life. These Filter Bag Finishes allow for customized solutions to meet specific application demands.

How It All Works: Anatomy of a Baghouse System

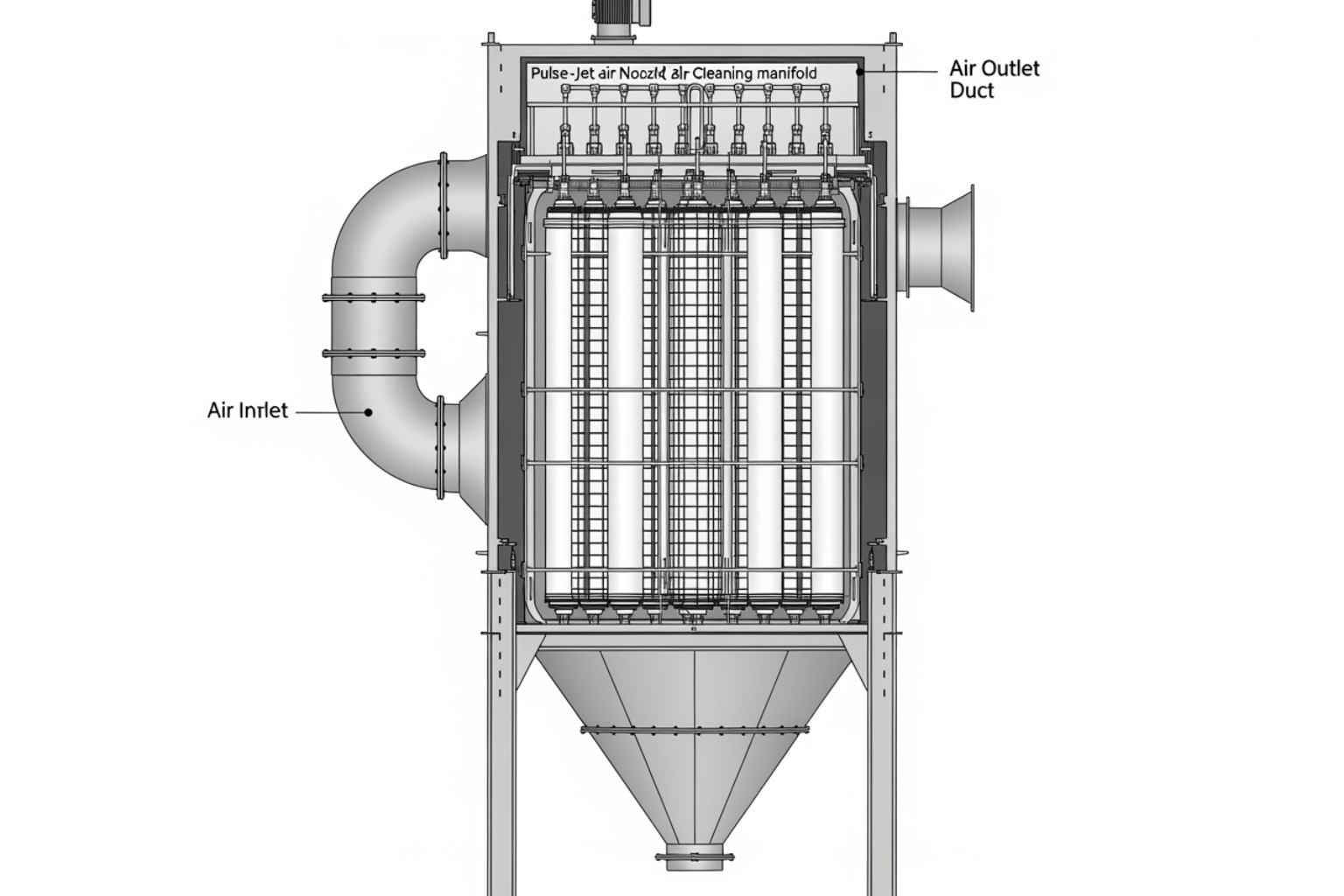

A baghouse is an engineered system where each component works to transform dirty industrial air into clean exhaust. To see how these parts work together, watch The Anatomy of a Baghouse.

From the moment dirty air enters until clean air exits, every component is designed to separate dust from air with maximum efficiency.

Housing, Hoppers, and Ductwork

The collector housing is a robust metal enclosure that contains the components and directs airflow to maximize filtration. A critical design choice is the High vs. Low Inlet Baghouse configuration, which impacts dust loading and wear. A well-designed inlet allows heavier particles to drop out of the airstream before reaching the baghouse dust collector filters, reducing the load on the bags.

Below the filters, the cone-shaped dust collection hopper collects dislodged dust. Screw conveyors or other mechanisms then transport the dust for disposal or recycling. Finally, ductwork connects the dust-generating processes to the baghouse, maintaining proper airflow velocity to prevent dust from settling in the pipes.

Fans, Cages, and Valves

The fan or blower creates the negative pressure that pulls contaminated air into the collector and filters the dust from the airstream. Without adequate fan capacity, the system cannot function effectively. Inside, each filter bag is supported by a filter bag cage, a wire framework that prevents the bag from collapsing during operation and cleaning cycles. Proper cage design is crucial for filter integrity and efficiency. We offer a wide selection of durable Dust Collector Cages.

Diaphragm and solenoid valves control the cleaning system. These precision components time the delivery of compressed or reverse air. In pulse-jet systems, solenoid valves trigger precisely timed bursts of air, which are delivered by the diaphragm valves. The reliability of these Dust Collector Valves directly impacts cleaning effectiveness.

Cleaning Systems

A cleaning system periodically removes accumulated dust from baghouse dust collector filters to maintain airflow and efficiency. Different methods offer distinct advantages.

Pulse-jet cleaning, used in our TubeJet Baghouse Dust Collectors, delivers short, powerful bursts of compressed air (80-100 psig) into the filter bags. This pressure wave flexes the fabric, dislodging the dust cake. While highly effective, this aggressive action can stress the filter media over time and consumes compressed air.

Reverse air cleaning, used in our Reverse Air Collectors, is a gentler method. It uses a low-pressure reverse airflow (3-15 psig) to slowly collapse the bags, causing the dust cake (collected on the inside) to fall into the hopper. This reduces mechanical stress and can extend filter life, but it may be less effective on sticky dusts.

Shaker cleaning uses mechanical vibration to shake dust loose from the inside of woven filter bags. This cost-effective method is suitable for intermittent-duty applications but is generally less thorough than pulse-jet or reverse-air systems, which can lead to declining efficiency.

The right choice depends on your dust, operating conditions, and performance goals. Our experience since 1902 helps you select the perfect cleaning system for your application.

Selecting and Maintaining Filters for Longevity and Cost Savings

Proper selection and maintenance of your baghouse dust collector filters are key to system longevity and cost savings. The right approach can extend filter life two to three times, lower operating costs, and prevent emergency shutdowns. Proactive maintenance, especially monitoring the pressure drop across your filters, is critical. Learn more in our guide on How to Monitor Baghouse Health Through Differential Pressure.

Factors for Selecting the Correct Baghouse Filter

Selecting the right filter requires matching the media to the application. Key factors include:

- Temperature: Process temperature dictates the material. Polyester is suitable for up to 275°F, while aramid (400°F), P-84 (460°F), or fiberglass are needed for higher temperatures.

- Dust properties: Abrasive dust requires durable media. Sticky or oily dust benefits from an oleophobic treatment or PTFE membrane for clean dust cake release. Fine particulate may require high-efficiency media to prevent blinding.

- Chemical resistance: The gas stream and dust chemistry are critical. Polypropylene works well against many chemicals at low temperatures, while PTFE offers broad resistance at high temperatures.

- Air-to-cloth ratio: This ratio of air volume to filter area determines filtration velocity. A ratio that is too high overworks filters, shortening their life and reducing efficiency.

Getting these factors right is crucial. For more details, see our guide on How to Select the Correct Filter Media.

Signs of Failing Baghouse Dust Collector Filters

Knowing the signs of failing filters can prevent major issues. Key indicators include:

- Visible emissions: Dust plumes from the stack signal filter failure and a compliance issue.

- High differential pressure: A pressure drop that remains high after cleaning indicates blinded filters that are no longer releasing dust properly.

- Reduced airflow: Weaker capture at pickup points suggests filters are obstructing airflow and choking system performance.

- Physical damage: Holes, tears, or excessive wear found during inspection are clear signs of failure. Dye testing can help locate hard-to-find leaks, as explained in our guide on Detecting Leaks in Your Baghouse System Through Dye Testing.

Ignoring these signs can lead to non-compliance, higher energy costs, equipment damage, and safety hazards. Knowing when to change filters is crucial. Learn more in 3 Reasons to Replace Your Dust Collector Filter Bags.

Staying Compliant: Safety and Environmental Regulations

Adhering to air quality standards and ensuring worker safety are legal and ethical imperatives. Your baghouse dust collector filters are critical for achieving both, protecting the environment, your people, and your bottom line.

Meeting EPA Emissions Standards

The Clean Air Act made fabric filter baghouses essential for meeting environmental regulations. With collection efficiencies greater than 99 percent, baghouse dust collector filters are indispensable for meeting strict standards for Particulate Matter (PM2.5) and MACT (Maximum Achievable Control Technology).

The right filter media is your first line of defense. For example, improper filter selection in an acidic environment can lead to corrosion, bag blinding, and emissions that exceed legal limits. The EPA provides detailed guidance on Monitoring by Control Technique – Fabric Filters, highlighting that compliance requires continuous monitoring and filters matched to your application’s demands.

NFPA Compliance and Fire Safety

When dealing with combustible dusts, a spark can lead to catastrophic fires or explosions. Specialized baghouse dust collector filters and system design are critical for safety. Anti-static filters prevent static electricity buildup that could ignite dust, while grounding straps provide a safe path for electrical charges to dissipate. See our video on NFPA Recommended Filter Bag Grounding Strap Design for details.

Fire safety also includes system-level features like explosion venting, which directs explosive force safely away from personnel and equipment. Our guide on How to Ensure NFPA and OSHA Compliance in Your Dust Collection System covers how all components work together to protect your facility and your people.

Frequently Asked Questions about Baghouse Dust Collector Filters

Here are answers to common questions about baghouse dust collector filters to help you make smarter decisions for your dust collection system.

How do different cleaning methods affect filter life?

The cleaning method significantly impacts filter life.

- Pulse-jet cleaning uses powerful bursts of compressed air (80-100 psig) to effectively remove dust. However, this force puts mechanical stress on the bags, which can shorten filter life if not properly tuned. Modern media and precise controls can minimize this wear. Learn more about Dust Collector Filter Cleaning: Compressed Air Requirements for Cleaning Bag Filters.

- Reverse-air cleaning uses low-pressure air (3-15 psig) to gently collapse the bags, releasing the dust cake. This kinder method can extend filter life but may be less effective on stubborn dusts and can require more maintenance.

- Shaker cleaning mechanically shakes bags to dislodge dust. It is cost-effective for intermittent use, but the physical agitation creates wear and tear, potentially leading to more frequent filter replacement.

Should I replace my filter bags or can they be cleaned?

While cleaning filters seems cost-effective, replacement is often the smarter financial decision. Cleaning can be a temporary fix, but filters can become permanently “blinded” when dust embeds too deeply for cleaning to restore airflow, especially with sticky or oily dusts.

Replacement is necessary when there is physical damage (holes, tears), differential pressure remains high after cleaning, visible emissions are present, or the filter media has degraded from age, heat, or chemical exposure. The combined cost of repeated cleaning, reduced efficiency, higher energy bills, and potential fines often outweighs the cost of new filters. We explore this in detail in Should I Replace My Filter Bags or Clean Them?.

What is the air-to-cloth ratio and why is it important?

The air-to-cloth ratio is the volume of air (CFM) divided by the total filter media surface area (sq. ft.). This ratio determines the filtration velocity, or how fast air moves through your filters. If the velocity is too high, dust can be driven deep into the fabric or pass straight through, reducing efficiency and shortening the life of your baghouse dust collector filters.

A high air-to-cloth ratio indicates an undersized system and leads to problems like high pressure drop, poor cleaning, and premature filter failure. A correct ratio allows the dust cake to form properly, maintaining high collection efficiency. Getting this calculation right is a fundamental step in designing an effective system, as shown in our Infographic: How to Design a Dust Collection System.

Conclusion

We’ve explored baghouse dust collector filters, from the variety of filter media like polyester, aramid, and PTFE to the different cleaning systems that keep them efficient. A simple fabric bag is a sophisticated piece of engineering, with finishes that can triple its working life.

Selecting the right baghouse dust collector filters is an investment in your facility’s future. Matching the filter media to your temperature, dust, and chemical environment ensures compliance with EPA and NFPA standards. It protects your workers, equipment, and bottom line from downtime and premature failures.

At Sly, LLC, we’ve been delivering reliable air pollution control solutions since 1902. From our facilities in Strongsville, Ohio, and Mathiston, Mississippi, we use our century of experience to solve any dust collection challenge. Understanding how your system works empowers you to make smarter operational decisions.

Your facility deserves a unique dust collection solution. Whether you face high temperatures, abrasive materials, or combustible dusts, we can help. Explore our full range of custom Dust Collectors to see how our expertise can deliver cleaner air, safer operations, and lower costs.